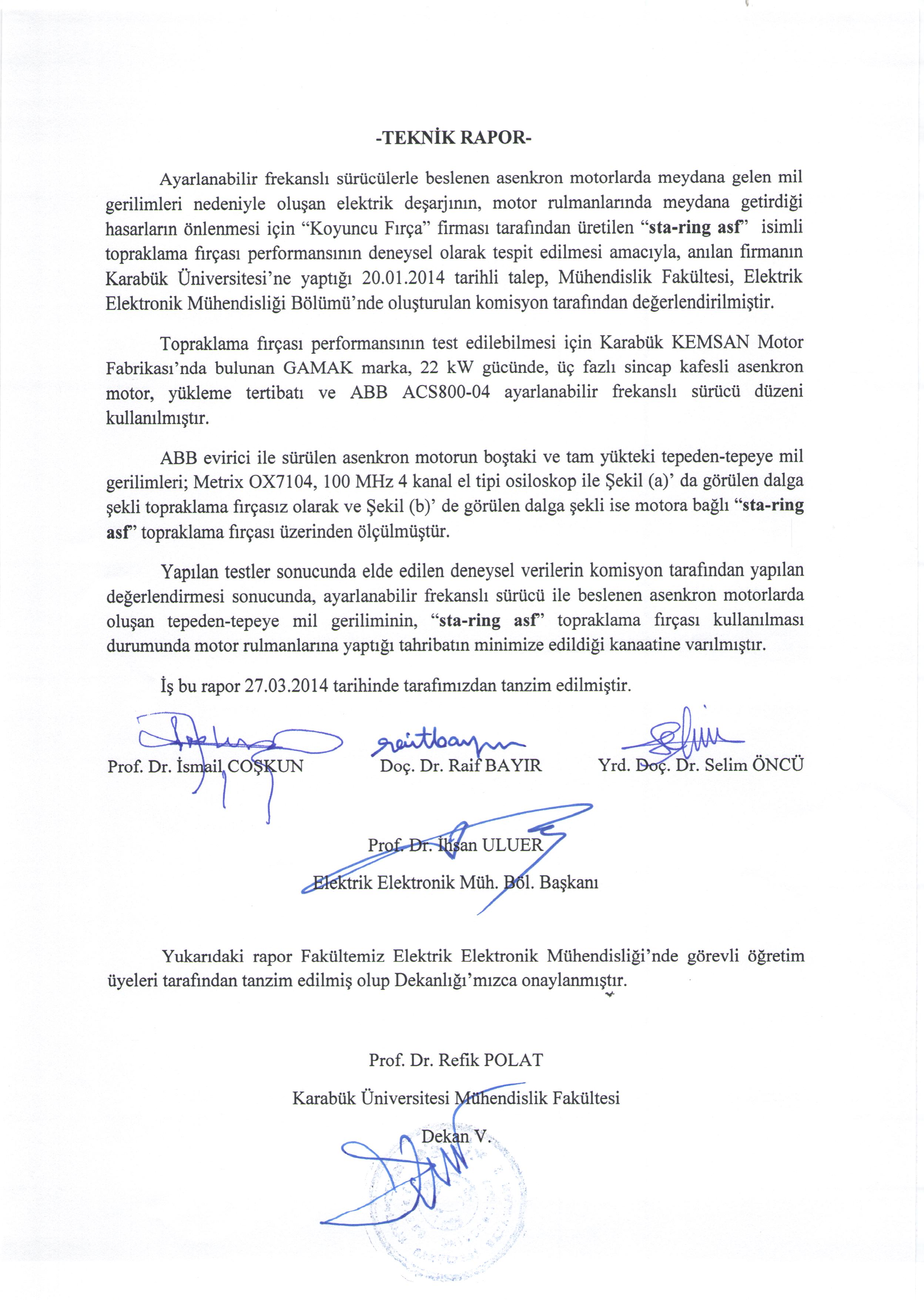

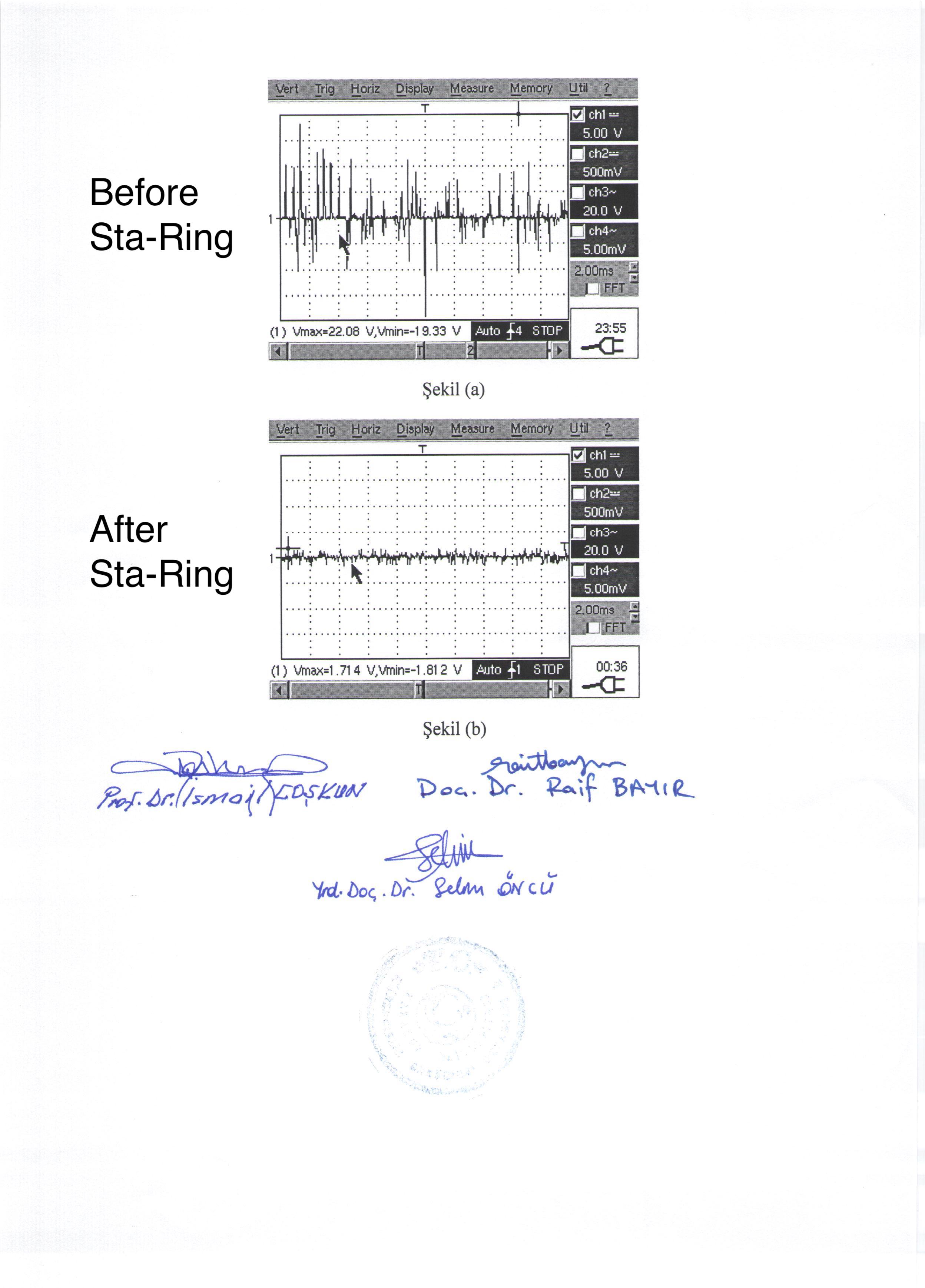

Sta-Ring ASF protects motor bearings and attached equipments from shaft currents and its contamination. Thanks to millions of conductive fibers it prevents currents to go over bearings. Thus, you can minimize unscheduled downtime, reduce high maintenance costs of the machine and its equipment

Features

- Sta-Ring ASF is not affected from dust, moisture or grease.

- Sta-Ring ASF is able to protect the bearings from damages thanks to thousands of discharge channels.

- Sta-Ring ASF is a low cost solution and can be applied to any AC –DC motors in all kinds of power level.

- Sta-Ring ASF dows not require any maintance.

- Sta-Ring ASF can be applied to either the drive end or the non-drive end of the motor.

- Sta-Ring ASF will not cause any damage or corrosion on shafts by help of microfiber bristles.

- Sta-Ring ASF can be produced in different sizes according to customer’s requirement.

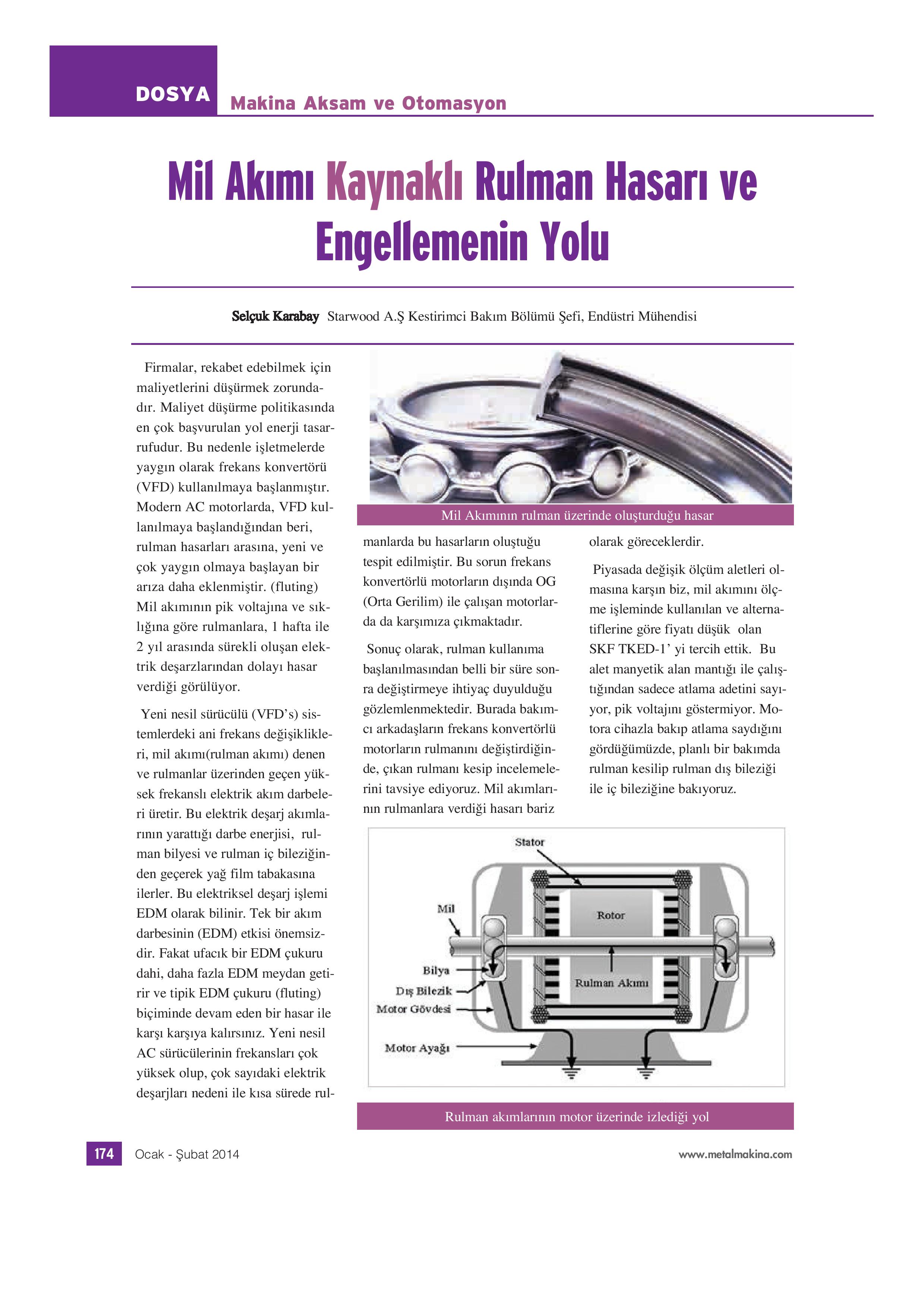

- Variable frequency drivers (VFD) has been used in industry in order to reduce the increasing energy cost. This industy innovation causes a new damage which is relatively unknown in the bearing damages.

- A parasitic capacitor occurs between the motor stator and the rotor as a result of dV/dt (voltage rise rate) which comes out during the operation of VFD. Therefore the voltage across the motor shaft increases over time. Occured shaft currents wants to move away from the system by following the easiast path.

- Since the shortest and the non-resistant paths on the system are bearings, shaft currents move awat from the system througt the bearings.

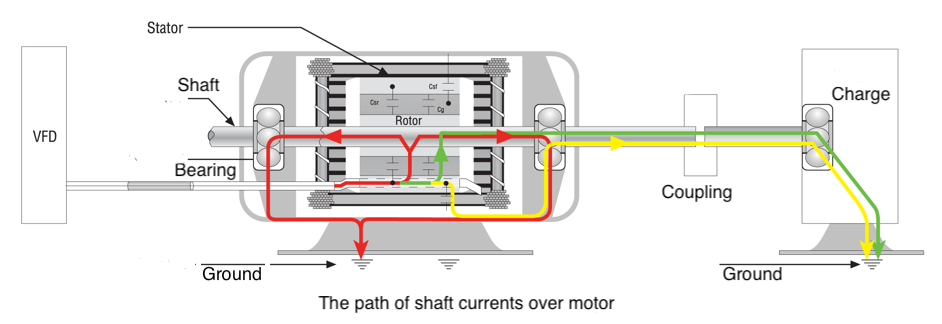

The current path shown in red is a coupled capacitive current in the rotor which passed through the return path bearings and througt the motor ground connection to ground. This path creates a current that passing througt the bearings which will cause a damage on bearings.

The path marked in green shows the current capacitively coupled to the rotor windings of the stator. This path causes damages in coupling on the engine pulley and to the coupling itself in some kind of couplings that connect the motor to the load.

The yellow current flows througt the frame, bearings, shaft, coupling, pulley side of the bearing, the load, load ground and driver ground. This current has also risk to damage the motor, bearings, pulley and the coupling.

The intense discharge currents on bearings causing craters, frosting and pitting on bearing sleeves. The number and depth of the pits formed on the bearings increases over time because of continious discharge currents.

Bearing damages in this kind causes high maintenance costs and production losses

DO NOT LET THIS HAPPEN TO YOUR BEARINGS.

Sta-Ring ASF has been developed with the latest technology to protect motor bearings and system equipment againt shaft currents and the damages they cause. It has a patented technology (patent no: 2013/04117) which creates a path that very small impedance of the shaft body and which involves maxi-conductive micro fibers capable of by passing the bearings completely.

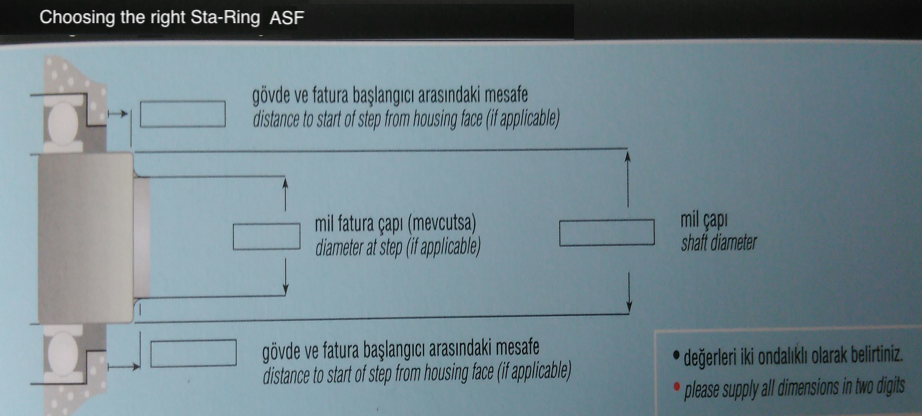

Sta-Ring ASF can be installed easily and quickly to all kinds of motor with 3 different kinds of manufacturing techniques.

- Sta-Ring ASF (One-piece shaft grounding ring)

- Sta-Ring ASF Split (2 pieces split shaft grounding ring)

- Sta-Ring ASF CHN ( Where the motor housing can not be drilled or punched, Sta-Ring ASF CHN can be easily mounted tı motor by its bonding channels.

Instructions

1- Be sure that the surface which the motor shaft and Sta-Ring ASF will come into contact, is cleaned of the paint and any other insulating material

2- Rotate the Sta-Ring ASF over the motor shaft and make it centered and then mark the locations of the mounting holes.

3- Drill mounting holes in the body with a diameter of 3 mm drill

4- Install Sta-Ring ASF to the body with the conductive screws. This is important because electrical current will pass througt the screws.

5- Sta-Ring ASF does not provide engine grounding. Motor frame must be well grounded to get the maximum parformance from Sta-Ring ASF.